It’s been about six months since we last posted so we decided to make an update.

Quite a lot has happened in the past six months. The Laguna Resaw Master arrived in May and after some modifications we finally got it running correctly and we were able to slice lots of sets for orders that had been delayed due to the equipment issues. We’d like to apologize to everyone we’ve kept waiting. Dealing with machinery issues in Hawaii is especially difficult.

We have a pallets worth of Koa instrument sets that we still need to go through and post online. Six months ago when we first launched the site we quickly listed tonewood sets as individual pieces (tops, backs and sides were individual items). We knew this wasn’t an ideal way to purchase sets but we needed to get our site online and we had lots of wood to cut at the time.

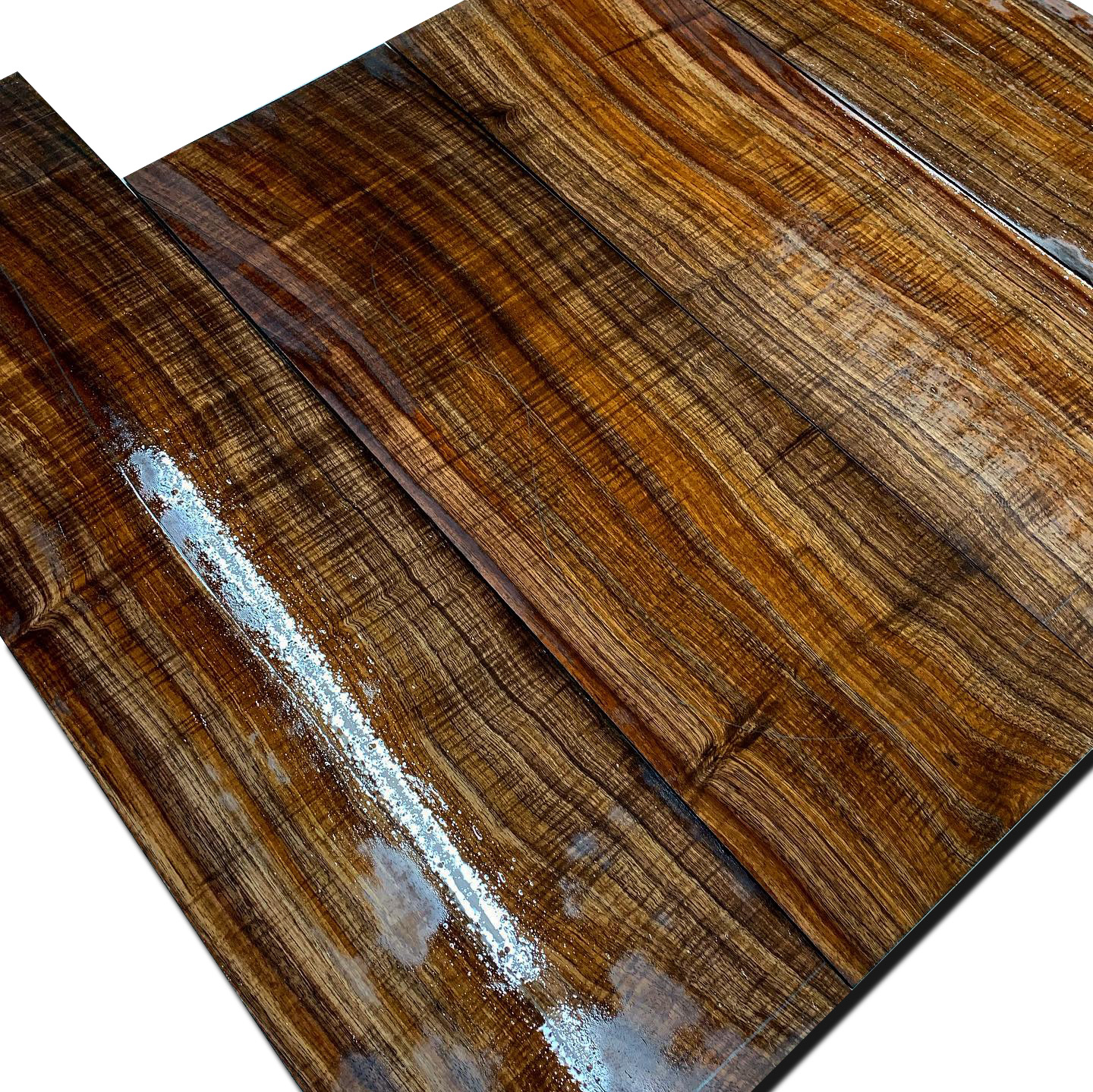

Now, we plan to list our Koa guitar and ukulele sets like this curly Hawaiian mango tenor ukulele set. We think this will be a much easier way to see exactly what we have in stock at the time.

We’re happy to take orders still, feel free to contact us, but please note that 5A Koa is extremely difficult to find right now and it might take some time before we can get more. We highly recommend that luthiers choose to use the lower grades of Koa in their production of guitars and ukuleles so that we can more consistently meet your needs. Using the lower grades also helps us to better use the resources of our precious forests.

Aside from tonewood sets, we also had some 4/4 and 8/4 Koa lumber that we kiln dried and surfaced on 4 sides. We posted the lumber we currently have here. We have about 75 more BF of select wood still in the kiln and there’s about 150 BF of old growth, super wide 8/4 boards that will make amazing guitars that’s still green (wet). We’re still in the process of separating the old growth lumber into tonewood for guitars and quarter-sawn billets but soon We’ll have some amazing tonewood sets online.

In addition to tonewood and lumber, we also processed Koa veneers in Japan. We contacted the owner of the veneer manufacturing equipment in Japan and they helped us bring the Koa veneer cant from factory to factory as it was processed into an 8 ft. x 4 ft. sheet of veneer.

The first factory sliced the cant and dried the raw veneers. The second factory took the raw veneers and book matched them together so they could be laid up at the third factory on a special fleece back material called Span Bond. The final veneer is only 0.6 mm thick and can be tightly rolled without cracking. It also has the benefit of unrolling and laying flat right away. You can find the 16 sheets that we currently have in stock here. My wedding ring is made of this same type of veneer so you really can roll it tight enough to wrap a finger.

Finally, we wanted to talk about the long term plans for Koality Woods. The goal of this company isn’t to take as much Koa and other woods from the forest. It’s quite the opposite in fact.

While every successful forestry management program requires proper maintenance of the forest, which sometimes means removing old or injured trees, we believe the primary goal of Hawaiian forestry should be to restore the Hawaiian forests to as close to their natural state as possible. We’re in the beginning phases of forming a massive reforestation effort across the state of Hawaii and hope to return the forests to their full potential across the state. We’re interested in talking with anyone looking to be apart of the initiative, please feel free to contact us.

Thanks for checking in!