Stabilized Curly Koa and Curly Mango Wood

Here you can learn about our process of stabilizing curly Koa knife scales, curly Koa pen blanks, call blanks, pistol grips, gun stocks and curly Koa pool cue blanks. We also stabilize curly Mango knife scales, pen blanks, call blanks, pistol grips, gun stocks and curly Mango pool cue blanks.

Harvesting Curly Koa Wood

The first step in stabilizing curly Koa wood and curly mango wood is to harvest the material from the Big Island, Hawaii. We only source responsibly harvested Koa wood from private landowners on the Big Island of Hawaii.

Dehumidification Kiln Drying

After we obtain responsibly harvested Koa wood and Mango wood we apply a coat of Anchorseal on the end grain and then stack the wood in our dehumidification kiln. This allows the Koa wood and Mango wood to safely dry through the face of the wood so no end grain cracking occurs. Once the Koa wood or Mango wood is finished drying to approximately 5-8% moisture content it’s removed from the kiln and then broken down with our band saw to knife scales, pen blanks, call blanks, pistol grips, gun stocks, curly Koa pool cue blanks and finally curly Koa chopsticks.

Purging the REMAINING Moisture COntent

Before the curly Koa and curly Mango wood is ready for the next phase of wood stabilizing, the final moisture content in the wood must be purged. The curly Koa and Mango wood blanks are placed in an oven for 24 hours at 220°F (105°C). After this curing phase they’re place in vacuum sealed bags so that no moisture from the ambient humidity can be absorbed in the wood as it cools.

Vacuum Stabilizing

With all of the moisture removed from the curly Koa or curly Mango wood, the blanks are ready for stabilization under vacuum. The blanks are placed in a vacuum chamber and a polymer blend is poured over the blanks. After the Koa wood blanks are fully submerged and the cap to the vacuum chamber is installed, a vacuum pump is used to draw out all of the air from the wood blanks. After all of the air bubbles are gone from the chamber the vacuum is removed and the curly Koa and curly Mango wood blanks are left to soak in the polymer resin.

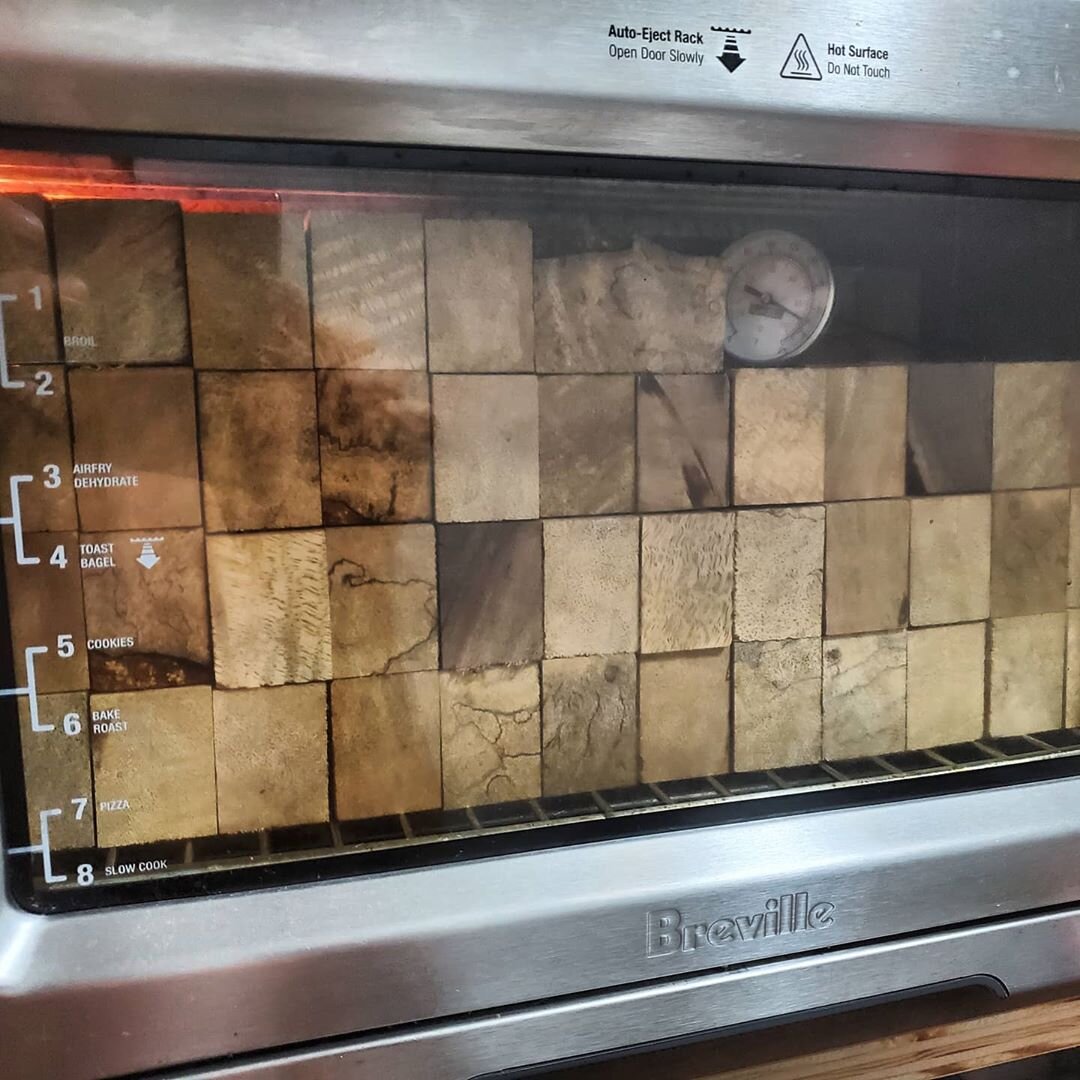

Curing the Polymer Resin

After 24 hours of soaking in the resin, the curly Koa wood blanks are now ready to be placed in an oven so the resin can be cured. The curly Koa wood or curly Mango wood blanks now have all of the air removed and the polymer has replaced the air in the plant cells. After baking in the oven at 200°F (94°C) the polymer is rock hard and the stabilized Koa wood is now extremely water resistant. The stabilized curly Mango or curly Koa wood is now heat resistant up to 400°F (205°C).

Prepping the Stabilized Curly Koa Blanks for online

After the curly Koa wood or curly Mango wood blanks are cooled, we sand all 6 sides up to a 220 grit before buffing. We use a 3 stage buffing process to show you the beauty of the curly Koa wood blanks. The first stage of buffing uses an all-linen Tripoli wheel and Tripoli compound to beginning the buffing process. We then use a softer, linen-cotton blend White Diamond buff and a harder, drier White Diamond compound. This removes the residue from the Tripoli and prepares the curly Koa wood blanks for the final polishing. The final step of the buffing process is done with an all-flannel wax wheel. Caranauba wax is used to produce a beautiful protective sheen on the curly Koa or curly Mango wood blanks.